0371-66362555

0371-66362555 18839785775

18839785775

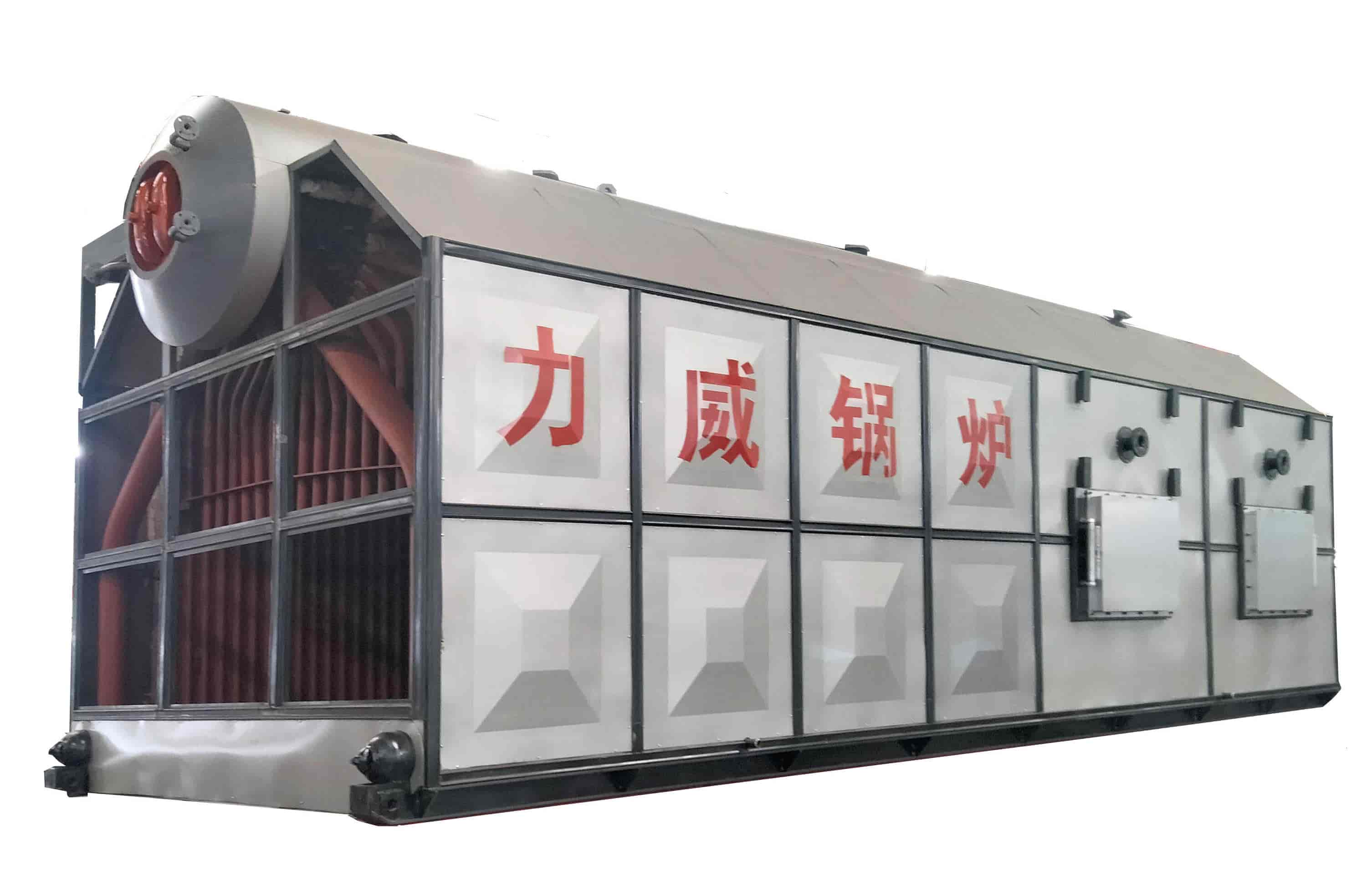

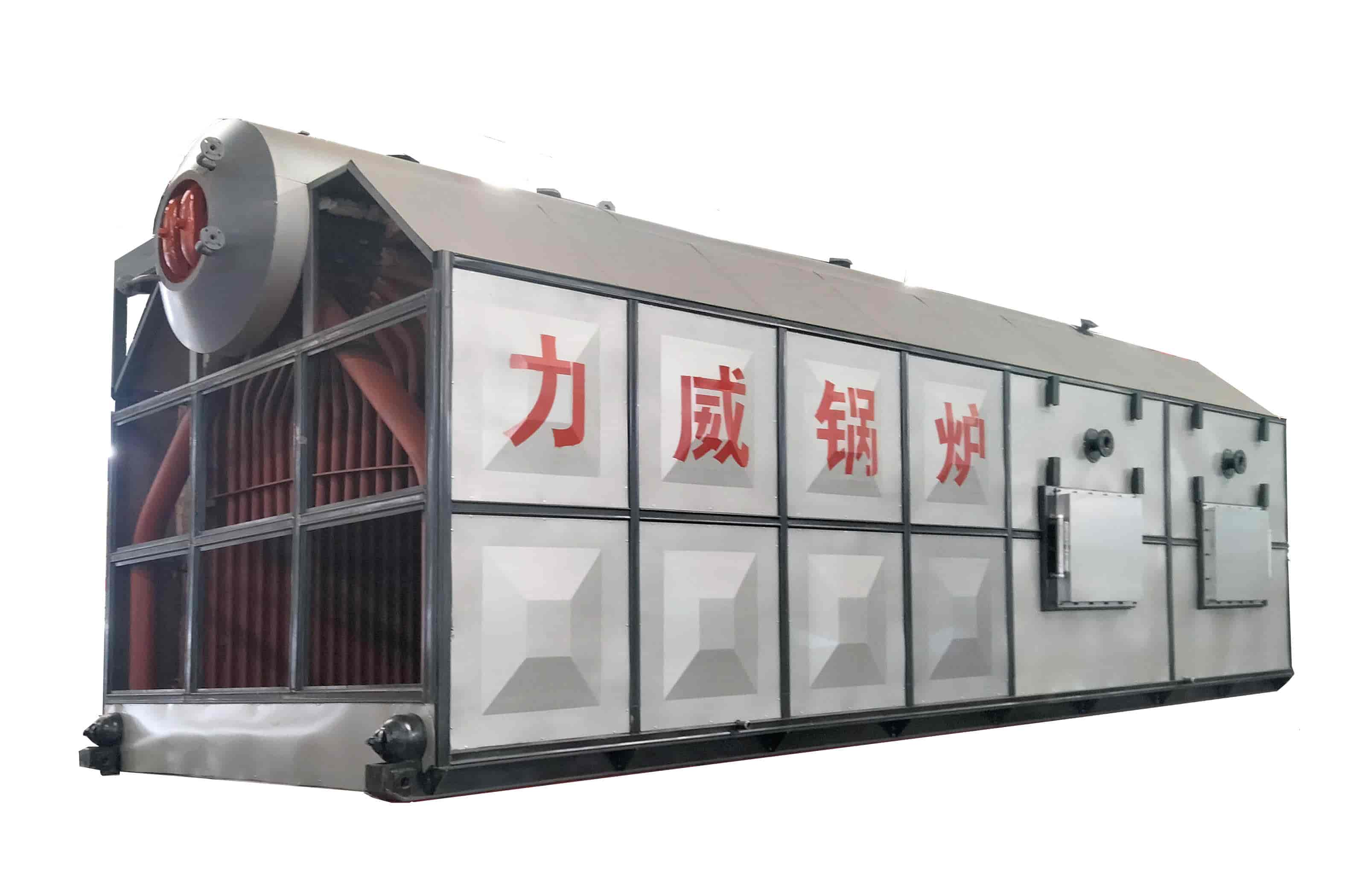

ok138cn太阳集团古天乐15吨SZL生物质锅炉又名双锅筒纵置式链条炉排锅炉,燃用生物质或固体成型燃料。炉膛两侧墙水冷壁采用膜式水冷壁结构;做工精良,用料扎实,注重细节,从精细化设计到材料生产,工艺严苛,精益求精。该15吨生物质锅炉炉膛两侧墙水冷壁采用膜式水冷壁结构;炉膛前、后墙水冷管向下延伸到炉排上部,形成前后拱。增加锅炉的密封性,同时增加了炉膛容积和受热面积,加固了后拱的强度。

SZL型组装水管锅炉,采用双锅筒纵置式布置,燃烧方式为链条炉排。额定蒸发量4~25t/h不等,上图锅炉蒸发量为15t/h。锅炉燃用生物质成型固体燃料。炉膛两侧墙水冷壁采用膜式水冷壁结构;炉膛前、后墙水冷壁管向下延伸到炉排上部形成前后拱,这样既增加锅炉的密封性能,又增加了炉膛容积及受热面,同时加固了后拱的强度。炉膛后为燃烬室、对流管束,尾部有省煤器。烟气经炉膛、燃烬室、对流管束、省煤器进入尾部烟道,通过除尘器、引风机、烟囱排入大气。前墙布置有二次风,由阀门控制,在燃用生物质燃料时投入使用,强化燃烧,使燃料充分燃尽,提高燃烧效率。采用较高的进料口,以满足生物质燃料的需要。

本锅炉分上下两大件出厂,上部大件包括锅炉本体、上部钢架及上部炉墙,下部大件包括煤斗、链条炉排、下部炉墙及内部通风道,除前后拱管及其连接管现场装配,部分砖墙及前后炉拱在现场砌筑外,其余部件均组装出厂,尾部省煤器及烟风道随锅炉配套出厂。尾部除尘器及其接管按照合同发货。

燃烧系统部分:燃烧系统包括煤斗、链条炉排、炉排传动装置。

本锅炉链条炉排为大块炉排片。炉排下面划分为数个独立的风室,根据燃烧情况配风,进风方式为双侧进风,进风均匀。前墙布置有二次风,由阀门控制,在燃用生物质燃料时投入使用。 炉膛前部设有料斗、闸门,用以调节进入炉排的料层厚度。炉排速度由减速箱控制调节。燃烧后的炉渣排入渣斗。

SZL系列水冷拱、膜式水冷壁组装锅炉是一种新型水管组装锅炉,它将大型链条炉排锅炉燃烧系统水冷拱技术及膜式水冷壁技术巧妙应用到组装锅炉上,技术指标处于国际水平。

SZL series shop-assemble water tubes boiler, which is a vertical type with double drums, uses chain grate as its combustion mode with rated evaporative capacity: 4-20t/h. this boiler uses shaped and solid biomass fuel, the two sides of whose furnace adopt membrane water-cooled wall structure. The tubes of water-cooled wall go down to the up side of the furnace which forms the front and rear arches so that the seal structure and intensity of back arch are enhanced and the cubic of the furnace and heating surface are enlarged. There are end combustion chamber and convection tube tank in the back of the furnace with fixing an economizer in the rear. After through the furnace, end combustion chamber, convection tube tank and economizer, the flue gas came into the flue duct in the rear, and then went by dust precipitator, induced draft fan &chimney, and was discharged into the air in the end. There is secondary air laying out in the front wall, which is controlled by valves and could be put into service to enhance the combustion and increase the combustion efficiency when using biomass fuel as boiler fuel. The height of feeding inlet is higher than usual to satisfy the need for biomass fuel.

This boiler is divided into two parts the upper part and the lower part before leaving the factory. The upper part involves boiler proper, steelwork and upper boiler setting, while the lower part involves coal hopper, chain grate, lower boiler setting and internal ventilating duct. Except site-assembled tubes of front & rear arches including its connection tubes and site-built part of the boiler setting with front & rear arches, the rests are packaged for duty with its economizer in the tail part and flue duct before leaving the factory, while the dust precipitator in the tail part and its connection tubes would be delivered according to the contract.

Combustion system:Combustion system involves coal hopper, chain grater and transmission device.

This boiler adopts mass fire grate flakes. And the wind is fed from both sides of the boiler by several independent air chambers below the grate to make flow uniform overall, which could be adjusted in accordance with the burning condition. There is secondary air laying out in the front wall, which is controlled by valves and could be put into service when using biomass fuel as boiler fuel. The feeder hopper and valves are installed in the front part of the furnace to regulate the thickness of the materials on the grate, whose speed is controlled by reduction box. Finally, after combustion, the slag will be discharged into the slag hopper.

SZL series water-cooled arch and membrane water wall assembly boiler is a new type of water pipe assembly boiler. It applies the water-cooled arch technology and membrane water wall technology of large chain grate boiler combustion system to the assembled boiler. The technical indicators are at the domestic leading level.

链条炉排蒸汽锅炉技术参数:

型号/参数/单位 | SZL6-1.6 -SCⅡ | SZL8-1.6 - SCⅡ | SZL10-1.6 -SCⅡ | SZL15-1.6 -SCⅡ | SZL20-1.6 -SCⅡ | SZL25-1.6 -SCⅡ | DZL2-1.25-SCⅡ | DZL 4-1.25 -SCⅡ | DZL 6-1.25 -SCⅡ | DZL 8-1.25 -SCⅡ | DZL 10-1.25--SCⅡ | ||

额定蒸发量 | t | 6 | 8 | 10 | 15 | 20 | 25 | 2 | 4 | 6 | 8 | 10 | |

给水温度 | ℃ | 20 | 20 | 20 | 104 | 104 | 104 | 20 | 20 | 20 | 20 | 104 | |

额定蒸汽压力 | MPa | 1.25/1.6(额定工作压力可按用户需求和标准系列选取) | |||||||||||

热效率 | % | 85.5 | 85.1 | 85.9 | 89.7 | 89.8 | 85 | 85.9 | 85.7 | 85.8 | 85.3 | 85.9 | |

锅炉水容量 | m³ | 7.5 | 9.2 | 11.8 | 11.85 | 18.5 | 20 | 4.48 | 6.5 | 7.5 | 8.07 | 11.8

| |

燃料消耗量 轻油 | Kg/h | 1266.7 | 1688.9 | 2111.1 | 3024.3 | 4032.4 | 5040.6 | 423.9 | 844.5 | 1263.7 .7 | 1686.7 | 2111.1 | |

烟囱直径 | mm | 700 | 900 | 900 | 1000 | 1100 | 1200 | 400 | 600 | 700 | 900 | 900 | |

锅炉大件重量 | t | 30 | 36 | 38 | 42 | 47 | 53 | 22.2 | 35 | 41.2 | 44.5 | 49.7 | |

大件运输尺 寸 | 长 | mm | 5370 | 7130 | 7853 | 9258 | 11396 | 11725 | 5100 | 6010 | 7180 | 7180 | 7246 |

宽 | mm | 2750 | 3180 | 3246 | 3294 | 3294 | 3671 | 2277 | 2860 | 2860 | 3210 | 3346 | |

高 | mm | 3535 | 3526 | 3528 | 3524 | 3524 | 3577 | 3492 | 3492 | 3528 | 3578 | 3578 | |

本 体外 形尺 寸 | 长 | mm | 7040 | 8230 | 9872 | 10736 | 12400 | 12800 | 5100 | 6010 | 7180 | 7180 | 7246 |

宽 | mm | 2830 | 3180 | 3294 | 3294 | 4220 | 4620 | 2277 | 2860 | 2860 | 3210 | 3346 | |

高 | mm | 5625 | 5726 | 5750 | 5774 | 8247 | 8247 | 3492 | 3492 | 3528 | 3578 | 3578 | |